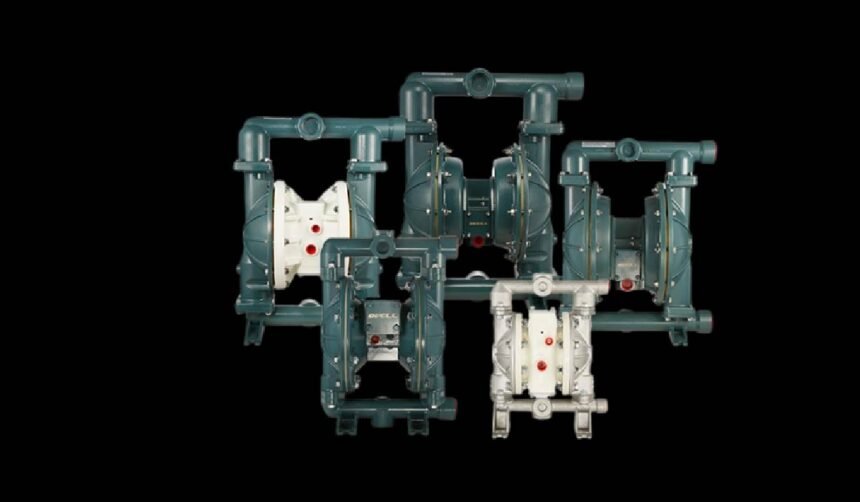

Maintaining a diaphragm pump in peak condition is essential for uninterrupted operations and cost-effective performance. A diaphragm pump is prized for its leak-free, seal-less design that handles corrosive, abrasive, and viscous fluids with minimal downtime. By following a structured maintenance regimen, you can significantly extend the service life of your equipment and safeguard your investment.

Understanding Your Diaphragm Pump

Diaphragm pumps separate the process fluid from mechanical components using a flexible membrane, eliminating dynamic seals that often fail in other pump types. This design makes diaphragm pumps inherently robust for demanding applications in chemical processing, water treatment, and food production. Familiarize yourself with your specific model—whether air-operated double diaphragm (AODD) or electric—to tailor maintenance practices effectively.

Routine Visual Inspections (Daily/Weekly)

- Leak Detection: Check the pump body, inlet/outlet connections, and piping for drips or seepage, which can indicate a compromised diaphragm or loose fitting.

- External Wear: Inspect for corrosion, dents, or damage on the housing, fasteners, and gauges to catch early signs of fatigue.

- Noise & Vibration: Listen and feel for unusual sounds or vibrations—rattles, grinding, or excessive humming often signal internal wear or air supply issues.

Monitoring Performance Metrics

Consistent monitoring of pressure and flow provides insight into pump health:

- Pressure Gauges: Track stable operating pressure; sudden spikes may indicate downstream blockages, while drops can point to suction issues or a worn diaphragm.

- Flow Rates: Record normal discharge rates; reductions often stem from clogged filters, worn check valves, or diaphragm fatigue (com).

Air Supply and Electrical System Care

- Air-Operated Models (AODD):

- Keep air filters clean to prevent dust and rust entry.

- Eliminate moisture and oil from the air line using dryers and lubricators as required; contaminated air accelerates diaphragm and valve wear.

- Electric Models:

- Inspect power cables and connections for cracks or frays.

- Ensure motor ventilation by clearing dust from cooling fins and verify proper grounding to avoid overheating and electrical faults (com).

Component Replacement & Advanced Maintenance

- Diaphragm Intervals: Follow manufacturer-recommended replacement schedules based on operating hours, fluid type, and temperature. Always install genuine Ovell® diaphragms for material compatibility and seal integrity.

- Check Valves: Clean and inspect valve balls and seats periodically; replace any showing pitting, swelling, or leakage to maintain prime and flow consistency.

- Air Valve / Motor: Lubricate or service the AODD air valve assembly per the manual. For electric units, check bearings and clean motor housing to preserve performance.

Best Practices for Storage and Staff Training

If the pump will be idle, drain and flush with a compatible fluid, then dry or fill with preservative according to guidelines to prevent corrosion. In cold climates, winterize components to avoid freeze damage. Invest in comprehensive training so maintenance personnel understand diaphragm pump operation, troubleshooting, and safety protocols.

A proactive maintenance strategy transforms pump upkeep from a reactive chore into a strategic investment. By adhering to routine inspections, monitoring performance, caring for air and electrical systems, and replacing wear-prone components on schedule, you safeguard uptime, reduce repair costs, and maximize the operational lifespan of your diaphragm pump. Regular training and proper storage further enhance reliability, ensuring your fluid transfer processes remain efficient and trouble-free for years to come.

For More Information Vist Timelymagazine