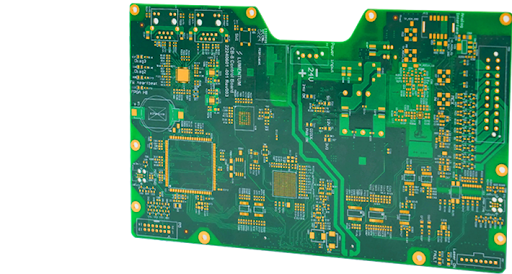

As electronics continue to develop, devices are becoming smaller, more powerful, and packed with functionality. Meeting these demands requires printed circuit boards (PCBs) that can handle high component density without compromising performance. This is where HDI PCB solutions come in. High-Density Interconnect (HDI) PCBs provide a compact, efficient, and reliable way to design advanced electronics, making them essential for modern gadgets, medical devices, and cutting-edge industrial equipment.

HDI PCBs allow engineers to place components closer together and create more complex circuits on a smaller footprint. By reducing the distance between connections, these boards improve signal integrity, reduce weight, and allow for faster, more responsive devices. For anyone developing advanced electronics, partnering with a provider like FastTurn PCB ensures access to high-quality HDI solutions that meet precise specifications while supporting rapid development cycles.

Understanding HDI PCBs

High-Density Interconnect PCBs are designed with a greater number of interconnections per unit area than traditional boards. They typically use microvias, blind and buried vias, and finer lines and spaces to achieve higher circuit density. These features allow HDI PCBs to accommodate advanced components such as microprocessors, sensors, and high-speed memory chips in compact devices.

Common applications include:

- Smartphones and Tablets – HDI technology supports smaller, lighter devices with more powerful performance.

- Medical Electronics – Compact diagnostic tools and wearable monitors require dense circuit designs without sacrificing reliability.

- Consumer Electronics – Laptops, smartwatches, and other gadgets benefit from miniaturized, high-density boards.

- Industrial and Automotive Systems – HDI PCBs provide robust, high-performance circuits that fit into limited spaces in modern machinery and vehicles.

By supporting complex designs in smaller areas, HDI PCBs help engineers innovate while maintaining high reliability and performance.

Advantages of HDI PCB Manufacturing

Choosing HDI PCB solutions provides several key benefits for electronics designers and manufacturers:

- Miniaturization – HDI boards allow for smaller, lighter, and more compact devices without sacrificing functionality.

- Improved Signal Performance – Shorter connection paths reduce resistance and crosstalk, ensuring higher signal integrity.

- Design Flexibility – HDI technology supports advanced multi-layer designs and complex circuit layouts.

- Enhanced Reliability – By reducing the number of interconnects and solder joints, HDI PCBs lower the risk of failure.

- Faster Time-to-Market – High-density designs allow prototypes and production boards to meet modern electronics demands efficiently.

These advantages make HDI PCBs an ideal choice for next-generation electronics where space, speed, and reliability are critical.

How FastTurn PCB Simplifies HDI Manufacturing

FastTurn PCB specializes in delivering high-quality HDI PCB manufacturing services that combine speed, precision, and innovation. Their expertise ensures that engineers can focus on design while relying on FastTurn PCB to handle the complexities of high-density manufacturing.

Key benefits of choosing FastTurn PCB include:

- Advanced Fabrication Technology – Utilizing microvias, fine line and space capabilities, and precision layer stacking to meet demanding specifications.

- Design Collaboration – Engineers can work with FastTurn PCB to optimize layouts, select materials, and reduce potential design issues.

- Rapid Turnaround – From prototype to production, FastTurn PCB accelerates timelines without compromising quality.

- Custom HDI Solutions – Boards can be tailored to meet specific requirements, including layer count, via types, and board thickness.

With these capabilities, FastTurn PCB ensures that HDI PCBs are manufactured accurately, efficiently, and reliably, making it easier for designers to bring advanced electronics projects to life.

Applications of HDI PCBs

The versatility and performance of HDI PCBs make them indispensable in many sectors:

- Consumer Electronics – Smartphones, tablets, and wearable devices rely on compact, high-density circuits.

- Medical Devices – From portable diagnostic tools to implantable sensors, HDI PCBs provide miniaturized, reliable solutions.

- Telecommunications – High-speed networking equipment requires compact, high-performance boards.

- Aerospace and Defense – Lightweight, compact, and robust HDI boards are essential for advanced navigation and control systems.

HDI technology allows designers to pack more features into smaller devices without compromising reliability or performance, making it a cornerstone of modern electronics design.

Conclusion

High-Density Interconnect technology is transforming the way electronics are designed and manufactured. HDI PCB solutions provide compact, efficient, and reliable boards that support advanced components, reduce device size, and improve performance.

For engineers and companies looking for precision, speed, and reliability in HDI manufacturing, FastTurn PCB is the trusted partner. Their expertise in high-density board fabrication ensures that your electronics projects are executed flawlessly, from prototype to production. By leveraging FastTurn PCB’s HDI solutions, designers can innovate faster, optimize performance, and bring next-generation devices to market with confidence.

![How to Style a Tennis Bracelet for a Perfect Chic Look [Timeless & Elegant Styling Ideas]](https://timelymagazine.co.uk/wp-content/uploads/2026/01/unnamed-2026-01-21T095644.608-150x150.png)