The evolution of modern electronics is driven by the demand for smaller devices, higher performance, and greater reliability. From wearable technology and medical equipment to aerospace systems and automotive controls, designers are constantly challenged to fit more functionality into less space. This is where a rigid flex circuit board combined with FastTurn PCB services provides an ideal solution for advanced electronic design and rapid production.

Rigid flex circuit boards merge rigid and flexible PCB technologies into a single unit, allowing the board to bend, fold, and fit into compact or complex spaces without sacrificing durability. When supported by FastTurn PCB manufacturing, these advanced boards can be produced quickly for prototyping and development, significantly reducing time to market.

What is a Rigid Flex Circuit Board?

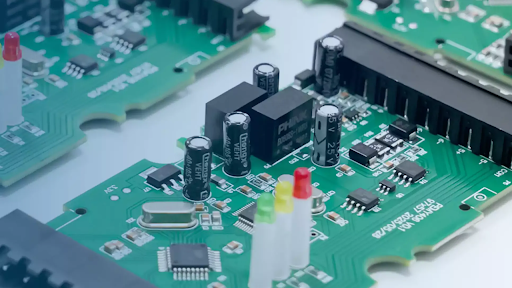

A rigid flex circuit board is a hybrid PCB made up of rigid board sections connected by flexible layers. The rigid portions provide stable mounting areas for electronic components, while the flexible sections allow the board to bend and conform to the shape of the device.

This structure eliminates the need for connectors, cables, and separate wiring between multiple boards. As a result, the overall assembly becomes more compact, lightweight, and reliable. The design also reduces potential failure points that are common in traditional PCB assemblies.

Rigid flex circuit boards are particularly valuable in applications where space constraints and mechanical stress are major concerns.

Key Advantages of Rigid Flex Circuit Boards

Space Optimization

The ability to fold and bend the board allows it to fit into tight enclosures and irregular shapes. This is ideal for compact electronics and wearable devices.

Improved Reliability

By removing connectors and reducing solder joints, rigid flex boards minimize the risk of connection failure and improve long-term durability.

Lightweight Design

The elimination of extra cables and connectors significantly reduces the weight of the device.

Better Electrical Performance

Shorter signal paths and fewer interconnections lead to improved signal integrity and reduced interference.

Greater Design Flexibility

Engineers can create innovative layouts that are not possible with traditional rigid boards.

Applications of Rigid Flex Circuit Boards

Rigid flex circuit boards are widely used across various industries, including:

- Medical devices such as monitoring systems and implants

- Aerospace and defense electronics exposed to vibration and extreme temperatures

- Consumer electronics like smartphones, cameras, and tablets

- Automotive electronics and control modules

- Industrial automation systems

These industries require PCBs that are compact, durable, and capable of withstanding challenging environments.

What is FastTurn PCB?

In addition to advanced design, speed is a crucial factor in modern electronics manufacturing. FastTurn PCB refers to rapid PCB prototyping and production services that deliver boards within a short timeframe, often within a few days.

FastTurn PCB services are particularly useful during the development phase, where engineers need to test designs quickly and make improvements without long production delays.

Benefits of FastTurn PCB Services

Rapid Prototyping

Engineers can receive rigid flex circuit board prototypes quickly, allowing immediate testing and validation.

Faster Development Cycles

Short turnaround times help reduce project delays and speed up product development.

Quicker Time to Market

Companies can launch products faster by minimizing waiting times for PCB fabrication.

Easy Design Modifications

When changes are required, FastTurn services allow quick revisions and re-production.

Combining Rigid Flex Circuit Boards with FastTurn PCB

The real advantage comes from combining rigid flex circuit board technology with FastTurn PCB manufacturing. Complex and compact boards that would normally take weeks to produce can now be delivered in days.

For example, a company developing a compact medical wearable can design a rigid flex circuit board that fits perfectly into the device and receive a prototype quickly. This allows engineers to test the fit, performance, and reliability early in the process, reducing the risk of costly errors later.

This combination is especially beneficial in industries where both innovation and speed are critical.

What to Consider When Choosing a PCB Manufacturer

When selecting a manufacturer for rigid flex circuit boards and FastTurn PCB services, consider the following factors:

- Experience with rigid flex technology

- Advanced equipment for precise manufacturing

- Ability to provide FastTurn PCB services without compromising quality

- Strong quality assurance and testing procedures

- Technical support for design optimization

A manufacturer with expertise in both areas ensures efficient production and high-performance results.

Conclusion

The growing demand for compact, high-performance electronic devices has made rigid flex circuit boards an essential solution for modern design challenges. These boards offer unmatched flexibility, durability, and space efficiency for a wide range of applications.

At the same time, FastTurn PCB services provide the speed required to prototype, test, and launch products quickly. Together, they enable businesses to innovate faster, reduce development time, and stay competitive in today’s fast-paced technology environment.

Whether for medical devices, aerospace systems, automotive electronics, or consumer gadgets, rigid flex circuit boards supported by FastTurn PCB manufacturing represent a smart and future-ready approach to electronics development.