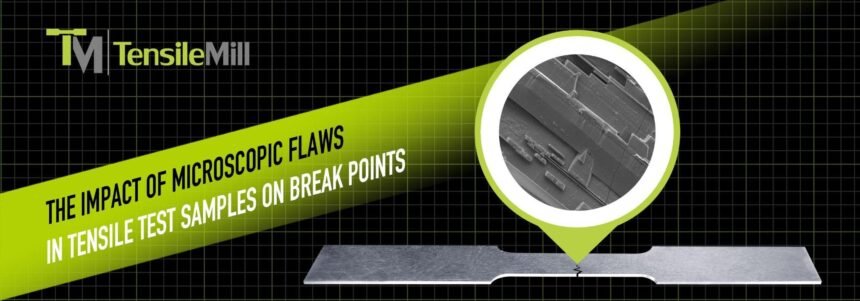

Tensile testing is a key process in materials science and engineering used to determine a material’s mechanical properties, including its strength, ductility, and fracture behavior. These tests are critical as they provide valuable data for selecting materials in the aerospace, automotive, and construction industries. However, even seemingly minor imperfections in a tensile test sample can lead to significant deviations from test results. Microscopic flaws, often invisible to the naked eye, can influence the material’s ability to withstand stress, leading to unexpected break point variations.

These flaws can occur naturally within a material or during manufacturing and processing. Although small, they can have a substantial impact on fracture mechanics as they create localized stress concentrations that accelerate failure. Engineers and scientists must account for these imperfections to guarantee accurate testing, reliable material performance, and safe engineering applications. Understanding how microscopic defects influence tensile test outcomes is crucial for improving material quality and refining testing methodologies.

Understanding Microscopic Flaws in Materials

Materials used in engineering applications are rarely perfect at the microscopic level. Even high-quality metals, alloys, and composites contain imperfections that affect their mechanical properties. These flaws may arise during raw material production, processing, or even as a result of environmental exposure over time. While some defects may be insignificant, others can weaken the material, leading to premature failure during tensile testing.

What Are Microscopic Flaws?

Microscopic flaws refer to tiny structural inconsistencies or defects within a material’s microstructure. These flaws can vary widely in size, shape, and origin, but they all influence mechanical performance under stress. Some common microscopic flaws include:

- Voids and Pores – Small air pockets or gas bubbles trapped within the material during solidification or processing. These voids reduce the overall density and load-bearing capability of the sample.

- Microcracks – Tiny cracks that may form due to internal stresses, improper cooling, or external fatigue over time. They act as weak points where fracture initiation is more likely to occur.

- Inclusions – Non-metallic particles embedded within the metal matrix, typically introduced during refining or manufacturing processes. These can disrupt material homogeneity and create stress concentrators.

- Grain Boundary Weaknesses – Irregularities in the arrangement of grains within a metal’s microstructure can lead to weaker intergranular bonding, making the material more prone to fracture along grain boundaries.

Even though these flaws are not always visible at a microscopic level, their presence can drastically alter tensile test results. When stress is applied, materials with microscopic defects often exhibit lower tensile strength, reduced ductility, and unexpected break points compared to defect-free samples.

How Do These Flaws Form?

Microscopic flaws can originate from multiple stages of material production and use. Manufacturing processes such as casting, forging, welding, and additive manufacturing (3D printing) often introduce imperfections due to uneven cooling, contamination, or mechanical stresses. Even after initial processing, additional factors such as heat treatment, machining, or surface finishing can introduce new defects or exacerbate existing ones.

In some cases, flaws also develop over time due to environmental exposure or operational fatigue. Materials subjected to repetitive loading, temperature fluctuations, or corrosive conditions may gradually accumulate microcracks, which weaken their integrity.

Influence of Microscopic Flaws on Tensile Test Outcomes

Microscopic flaws, while often undetectable without specialized equipment, can significantly alter tensile testing results. These imperfections affect the way stress is distributed throughout the material, creating weak points that influence break locations, failure modes, and mechanical properties.

One of the most noticeable effects is a reduction in tensile strength. When a material is pulled under load, flaws disrupt its uniform stress distribution. Instead of the entire structure bearing the applied force evenly, localized stress concentrations form around defects, leading to premature failure. A sample that appears structurally sound may fracture at a lower-than-expected force simply because an internal flaw weakens a specific region. This phenomenon is particularly concerning in industries where materials are expected to withstand extreme loads, such as aerospace and automotive engineering.

Ductility, which represents a material’s ability to deform before breaking, is also significantly impacted. A flawless metal sample might stretch considerably under tension, providing clear signs of impending failure before reaching its breaking point. However, if microscopic flaws are present, the material may exhibit brittle behavior, breaking suddenly with minimal elongation. This lack of warning can be dangerous in real-world applications where controlled deformation is necessary to absorb energy and prevent catastrophic failures.

The way a material fractures during tensile testing can also reveal valuable insights into microscopic flaws. In a pure, defect-free material, fractures often occur predictably, following expected stress patterns. However, when flaws are present, the fracture path becomes irregular, sometimes propagating through grain boundaries or along unexpected planes. This irregularity makes it difficult to interpret tensile test results accurately, as the measured properties may not reflect the actual performance of a properly manufactured or defect-free version of the same material.

When interpreting tensile test outcomes, it is necessary to consider the possibility of microscopic flaws influencing the data. Without acknowledging their presence, engineers might make incorrect assumptions about a material’s strength, leading to design failures. Identifying and understanding these defects is critical to refining material selection, manufacturing processes, and testing methodologies.

Testing Equipments’ Role in Detecting and Mitigating Flaws

Accurate tensile testing relies on more than just the sample itself—it also depends on the precision of the testing equipment and the ability to detect hidden defects before they compromise results. Modern tensile testing machines apply controlled forces while gathering detailed material response data. However, without complementary testing methods to examine a sample’s microstructure, flaws can remain undetected until they cause unexpected mechanical property variations.

Advanced microscopy techniques, such as scanning electron microscopy and optical microscopy, allow researchers to inspect tensile test samples before testing begins. These tools help identify voids, inclusions, and microcracks that could influence the final results. Non-destructive testing methods, including ultrasonic and radiographic testing, offer additional insights by detecting subsurface flaws that might not be visible externally. Combining these techniques with tensile testing will provide a more comprehensive understanding of material behavior.

There can be no doubt about the importance of controlled manufacturing processes. Many industries implement strict quality control measures to reduce flaws. Precision machining, refined heat treatment techniques, and careful material selection minimize defects that could interfere with tensile test results. Even the way a test sample is prepared—how it is cut, shaped, and polished—affects its reliability. A poorly prepared specimen may introduce artificial flaws, leading to misleading test outcomes.

One of the most effective ways to minimize errors in tensile testing is through CNC machines and tensile sample preparation equipment. These machines allow for precise and repeatable test specimen preparation, resulting in consistency in shape, dimensions, and surface finish. Sample preparation machines designed specifically for tensile testing applications help prevent irregularities that could introduce unwanted variables into test results.

Assuring Accurate Tensile Testing Through Flaw Awareness

Microscopic flaws may be small, but their impact on tensile testing is notable. These imperfections alter how materials distribute stress, affecting their strength, ductility, and fracture behavior. The presence of voids, inclusions, and microcracks can cause premature failure, making materials appear weaker or more brittle than they would be in a flawless state. Recognizing this influence is a necessity for engineers who rely on tensile testing data to guide material selection and structural design.

Accurate testing does not stop at applying force to a specimen. It requires careful sample preparation, defect detection, and advanced testing equipment to be certain that the results truly reflect the material’s properties. By understanding and accounting for microscopic flaws, industries can improve material reliability, boost safety, and develop stronger, more durable components for engineering applications.