Choosing the right centrifugal pump manufacturer isn’t just about specs on a datasheet. For plant engineers, maintenance heads, and purchase leads, it’s about knowing the equipment will run consistently in high-risk, high-volume environments—without causing chemical exposure, asset breakdown, or process delays.

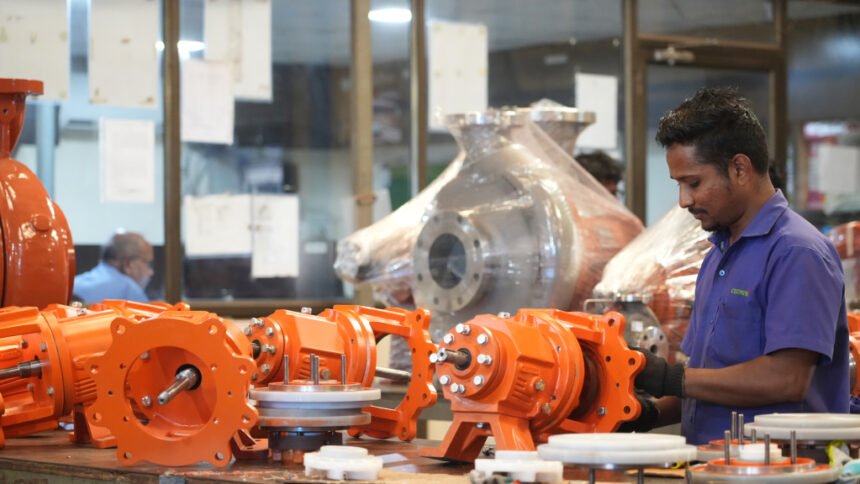

Among centrifugal pump manufacturers in India, Chemitek Process Equipments stands apart by doing more than selling pumps. They engineer process reliability into every product that leaves their floor. And that matters when you’re pumping hydrochloric acid at 85°C, handling abrasive slurries, or emptying solvent barrels in under 3 minutes flat.

Here’s a deep dive into what makes Chemitek a partner of choice across chemical, pharma, steel, and water treatment plants.

1. Custom Engineering Beyond the Standard Curve

Not every pump needs to be custom. But every process does.

At Chemitek, engineering starts with process realities, not brochure templates. The team often works with incomplete datasheets, unexpected chemical blends, or line fluctuations that generic OEMs won’t touch.

Here’s how Chemitek tackles that challenge:

- Application-first design: The pump is sized only after understanding flow dynamics, head variations, and media reactivity.

- Built-to-suit hydraulics: Impeller profiles and casing geometries are modified in-house to suit batch or continuous duty.

- Tolerance engineering: Pumps are designed to allow minor misalignments, voltage fluctuations, and startup shock loads common in Indian industrial plants.

2. Dual Material Expertise: Metallic & Non-Metallic Mastery

Most manufacturers specialise in either metallic or non-metallic builds. Chemitek does both with design, material selection, and testing teams trained across domains.

Non-Metallic Pumps That Withstand 210°C

Chemitek’s non-metallic (NM Series) pumps are available in:

- PP: For neutral media and basic acid/alkali transfer

- PVDF: For aggressive acids up to 90°C

- FEP-lined: For oxidising solvents like nitric or chromic acid

- ETFE: For high-purity and high-abrasion applications

These materials are chosen based on 15+ years of chemical compatibility data.

Metallic Pumps Built for Rugged Duty

Chemitek uses investment-cast SS316, Alloy 20, and Hastelloy builds for:

- High-pressure and temperature operations

- Slurry and suspended-solid media

- Chloride-rich corrosive environments

Every pump is matched to its application using in-house chemical-material compatibility matrices.

3. Proven Innovation Track Record in Sealing and Safety

Chemitek provides two key sealing technologies across its centrifugal pump lineup:

- IMSS (Internal Mechanical Seal – Single)

- IMSD (Internal Mechanical Seal – Double)

These seal systems are engineered for:

- Viscous and corrosive chemical media: Ideal for handling slurries, acids, or solvents that challenge conventional seals

- Enhanced thermal resistance: Suitable for elevated temperatures often encountered in chemical processing

- Maintenance convenience: Modular designs simplify inspection and replacement, minimising downtime

For hazardous or highly volatile applications where leakage must be completely eliminated, Chemitek also manufactures magnetic drive centrifugal pumps that feature:

- Seal-less design: Prevents chemical exposure from seal failure

- Synchronous magnetic coupling: Enables power transmission without a direct shaft connection

- Optional water-cooled housings: Provide added thermal control when handling exothermic or heated fluids

These magnetic drive pumps are especially preferred in industries requiring absolute containment of fluids, such as pharmaceutical and specialty chemical manufacturing.

4. ANSI/ASME B73.1 Compliance for Global Fitment

Chemitek’s metallic centrifugal pumps follow ANSI/ASME B73.1 standards. This is critical for Indian OEMs and EPC contractors exporting equipment to the U.S., Gulf, or Southeast Asia.

Benefits:

- Plug-and-play replacement for U.S.-spec systems

- Easy integration into export projects and EPC installations

The company ensures footprint and nozzle dimensions are compatible with global systems while retaining application-level customisation.

5. Application Coverage That Extends Across 15+ Industries

Chemitek isn’t locked into one segment. Its pumps have handled everything from ethanol in distilleries to caustic brine in chlor-alkali units.

Trusted in Everything from Chemicals to Breweries

Chemitek centrifugal pumps are used in:

| Industry | Application Examples |

| Chemicals | Acid/alkali transfer, chlorinated solvents |

| Pharma | Solvent dosing, clean-in-place loops |

| Steel Plants | Acid regeneration, pickling bath circulation |

| Food & Beverage | Cleaning fluids, water circulation |

| Distilleries | Ethanol, molasses slurry pumping |

Built to Handle Abrasive Slurries, Acids, Alkalis, Solvents

Whether it’s a shear-sensitive polymer slurry or a highly reactive oxidiser, Chemitek’s pumps are built to:

- Maintain flow uniformity

- Prevent seal failure under abrasive load

- Avoid product contamination

6. Export Footprint and Global Scalability

Chemitek is not just built for India. The company has a growing footprint in high-regulation markets and export-centric EPC projects.

Already Trusted in Egypt, UAE, SA, and Southeast Asia

Chemitek’s pumps are operational in:

- Chlor-alkali plants in Saudi Arabia

- Chemical drum transfers in Egypt

- Effluent treatment systems in the Philippines

- API manufacturing facilities in Vietnam

USA-Ready in Specs, Safety, and Compliance

The team has developed a specific export series with:

- UL/CSA-compatible motor designs

- ANSI flanges and NEMA standards

- Custom paint systems for Gulf and South Asian climates

This makes Chemitek a viable OEM partner for global pump orders.

7. End-to-End Reliability: From Design to Maintenance

Chemitek doesn’t walk away after dispatch. The pump’s field performance is tracked from commissioning to overhaul.

Back Pull-Out Designs & Easy Serviceability

All Chemitek centrifugal pumps have back pull-out designs:

- Pull out the rotating assembly without disturbing the suction/discharge pipe

- Faster service during planned maintenance

The company also offers:

- Spare kits with pre-assembled seals

- Remote commissioning assistance

- Service contracts for critical plants

Lifecycle Cost Advantage Through Engineering, Not Just Pricing

Chemitek helps reduce the total cost of ownership (TCO) through:

- Longer MTBF (Mean Time Between Failures)

- Optimised energy use per transfer cycle

- Material combinations that reduce internal corrosion by 60%+

It’s not just about the initial capex. Chemitek pumps justify themselves with every maintenance cycle you skip and every fluid transfer that runs without shutdown.

Conclusion

Among centrifugal pump manufacturers in India, Chemitek offers a proven blend of chemical know-how, industrial engineering, and hands-on support.

They build for real-world complexity, not ideal conditions, making them a dependable partner for aggressive process media and export-scale projects.